Materials processing

High temperature annealing in vacuum The cleanroom of the Solid State Physics laboratory is equipped with a vacuum chamber designed to perform thermal annealing processes in vacuum at high temperature.

The vacuum system consists of a turbomolecular pump coupled with a mechanical diaphragm pump, allowing a minimum operating pressure of ~5×10-7 mbar. Inside the chamber, a mm-sized sample can be inserted in a resistive heater consisting in a pair of molibdenum thin sheets shaped in the form a cavity, in order to keep the sample in thermal equilibrium with the surrounding black-body radiation emitted by the heater. The maximum operating temperature is 1500 °C. The sample temperature is externally monitored though an optical window by means of a pyrometer, and the whole system is controlled by a computer that sets the current flowing through the heating element as a function of the set temperature, with a P-I-D thermostating cycle. The control system allows for the definition of arbitrarly complex annealing cycles. |

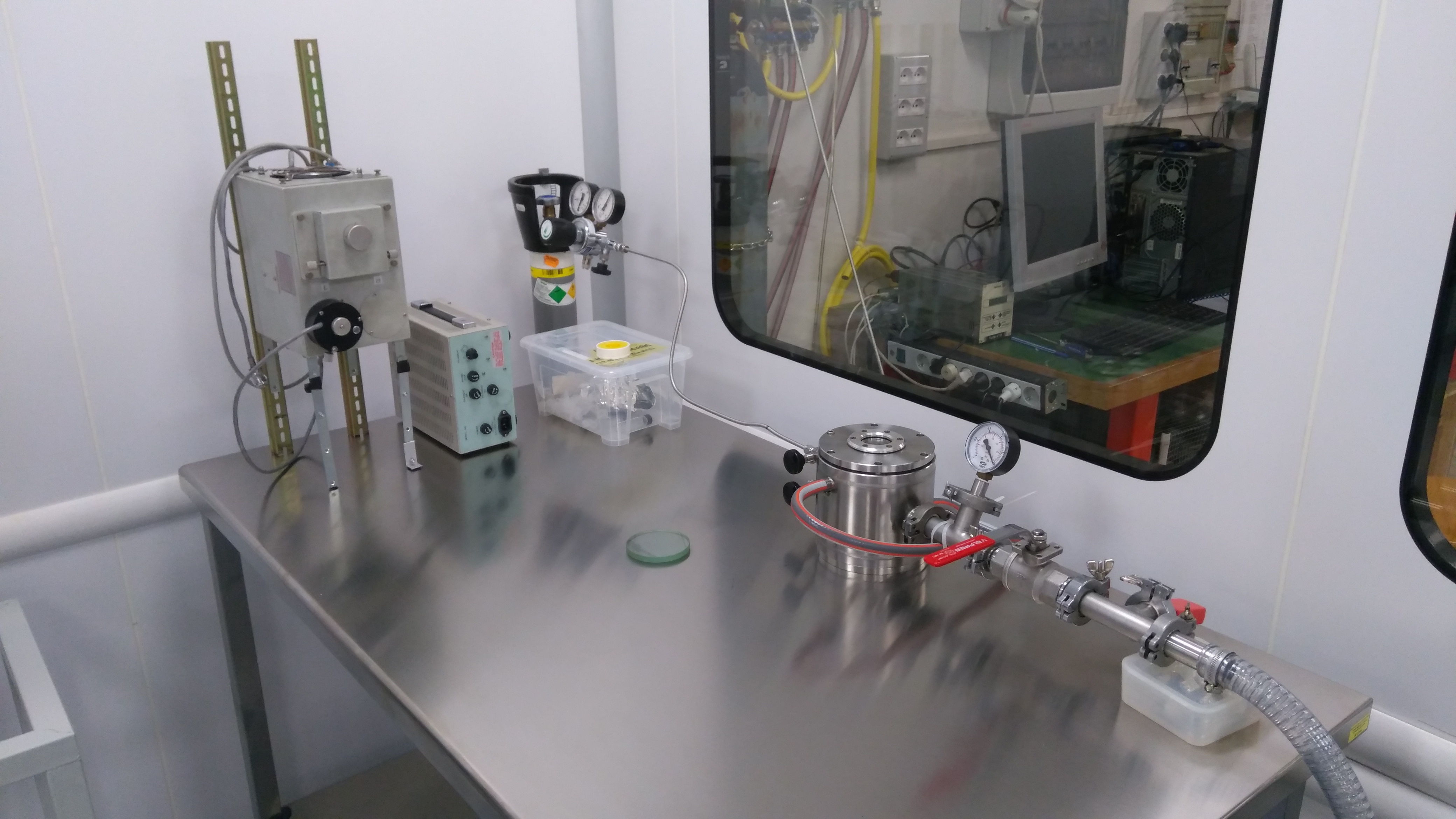

Medium-high temperature annealing in controlled atmosphere The cleanroom of the Solid State Physics laboratory is equipped with a vacuum chamber designed to perform thermal annealing processes in controlled atmosphere at medium-high temperature.

The vacuum system consists of a mechanical diaphragm pump, allowing a minimum operating pressure of ~5×10-2 mbar. After pumping, it is possible to flow high-purity gases (N2, O2, Ar, etc.) into the chamber at controlled pressures (both below and above room pressure). Inside the chamber, a cm-sized (i.e.: max 5 cm) sample can be placed onto a resistive heating stage. Differently from the previous case in which thermal conduction is mainly due by irradiation, in this apparatus the presence of gases in the annealing chamber determine a much more effective heat exchange. For this reason, the chamber walls are cooled with a continuous water flux during the process, in order to avoid the heating of the surrounding instrumentation. The maximum operating temperature is 800 °C. The sample temperature is monitored by means of a thermocouple integrated with the heating stage, and the whole system is controlled by a computer that sets the current flowing through the heating element as a function of the set temperature, with a P-I-D thermostating cycle. The control system allows for the definition of arbitrarly complex annealing cycles. |

Plasma cleaner The cleanroom of the Solid State Physics laboratory is equipped with a ZEPTO plasma cleaner which is routinely employed to remove impurities and contaminants from surfaces through the use of an energetic oxygen plasma produced by a 40 kHz / 100 W generator. The process operates at a base pressure of 0.3-1 mbar created with a mechanical pump and only requires few minutes.

|